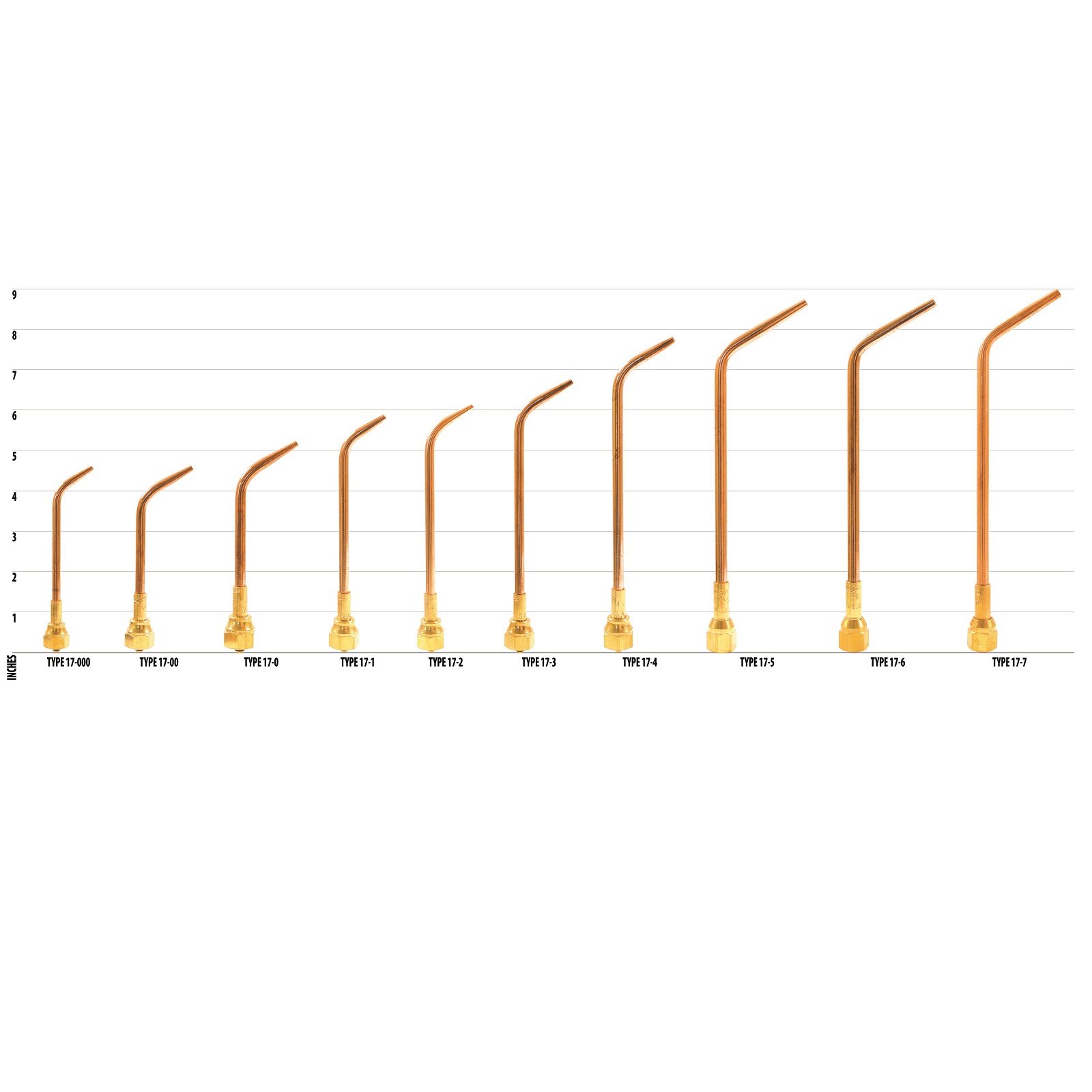

Product Information

| Part# | Acetylene Consumption SCFH | Fuel PSIG | Oxygen PSIG | Welding Metal Thickness | Brazing Copper Tubing | Replacement Elbow | Replacement Mixer & Nut UM17 |

|---|---|---|---|---|---|---|---|

| Type17-000 | 1-2 | 5 | 5 | 1/32″ | 1/8″ | n/a | n/a |

| Type17-00 | 2-3 | 5 | 5 | 3/64″ | 1/4″ | n/a | n/a |

| Type17-0 | 2-4 | 5 | 5 | 5/64″ | 1/2″ | n/a | n/a |

| Type17-1 | 3-6 | 5 | 5 | 3/32″ | 3/4″ | n/a | n/a |

| Type 17-2 | 5-10 | 5 | 5 | 1/8″ | 1″ | n/a | n/a |

| Type17-3 | 8-18 | 6 | 7 | 3/16″ | 1″-1/2 | n/a | n/a |

| Type17-4 | 10-25 | 7 | 10 | 1/4″ | 2″ | n/a | n/a |

| Type17-5 | 15-35 | 8 | 12 | 1/4″ to 1/2″ | 3″ | n/a | n/a |

*NOTE: When acetylene weld/braze tips are used with fuel gases, use one size larger tip and maximum pressures to obtain proper heat. The chart indicates the approximate torch oxygen consumption with a neutral flame ratio for various gases: Pressures are approximate for hose length up to 25 ft.; increase for longer lengths about 3 PSIG per 25 ft.-increase working pressure 2-3 PSIG for check valves and flashback arrestors. Acetylene delivery pressure should not exceed 15 PSIG under flow conditions.

-o-

-o-